First-Year Students Build Computer-Controlled Machines that Decorate Cakes, Print Braille, Play a Pennywhistle

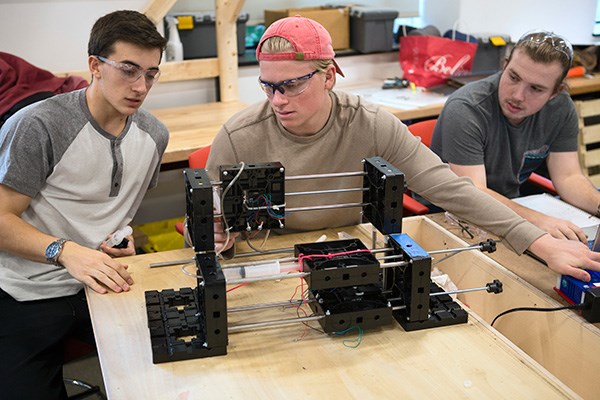

From left: Students Michael DelGenio, Aidan Burbridge and Piero Pocobene test and debug the computer code for their prototype “Automated Hotdog Condiment Dispenser” machine.

04/12/2017

By Edwin Aguirre

Nine sections of mechanical engineering freshmen built their own computer-controlled machines in the MakerSpace facility on North Campus last semester, creating whimsical devices that did everything from dispensing ketchup and mustard to “printing” pancakes.

It was the successful culmination of a three-year experiment to improve hands-on learning opportunities for first-year students in mechanical engineering. The labs for Introduction to Mechanical Engineering were developed by a faculty team under a $200,000 National Science Foundation grant.

“I was impressed with the students’ creativity,” says Assoc. Prof. David Willis. One team printed pancakes using a machine resembling a 3-D printer that dispensed pancake batter, instead of plastic, onto a heated plate. “I was surprised at how perfectly the pancake was formed and cooked by their machine. A very tempting treat for any engineer!” Willis says.

In the process, the students learned as much about MatLab, a high-performance language for technical computing, as previous students have learned by their junior or senior year, Willis says: “We find the students are passionate about developing something that works. It changes their perspective on computer programming.”

Willis, Prof. Sammy Shina and Asst. Prof. Christopher Hansen in mechanical engineering and Assoc. Prof. Stephen Johnston in plastics engineering developed the lab protocol in stages under the 2013 “Hands-on MADE 4 ME” grant. They started by buying off-the-shelf computer numerical control machines (CNCs) and hiring a graduate student to assemble them. Students learning MatLab would follow certain programming “recipes,” then hook their laptops up to the CNC machines to see if their code worked.

Then the professors took it a step further. They designed a basic component – 6-inch-square black plastic modular block with various holes and compartments – that could be assembled into machines using off-the-shelf hardware. In their first lab assignment, students assemble three of them to make a device with a small motor that, when hooked up to a controller, moves one of the blocks along threaded rods strung between two more blocks.

Elijah Gerrior, who’s taking the class this spring, says he enjoys putting theory into practice in the lab: “You get that extra component of hands-on work right from the start.”

Kristopher Tite, a senior who worked as a lab assistant last semester – and made 2,000 modular blocks over the summer for this year’s freshman students to use – says the labs are much better than when he took the class. Instead of following standard programming recipes, this year’s students are researching more advanced MatLab programming to realize their ideas, he says.

“That’s pretty darn cool, to have their final project come to life.”