The U.S. Department of Energy (DOE) recently recognized Stephen T. Lam, an assistant professor of chemical engineering, with an Early Career Research Program award worth $876,564.

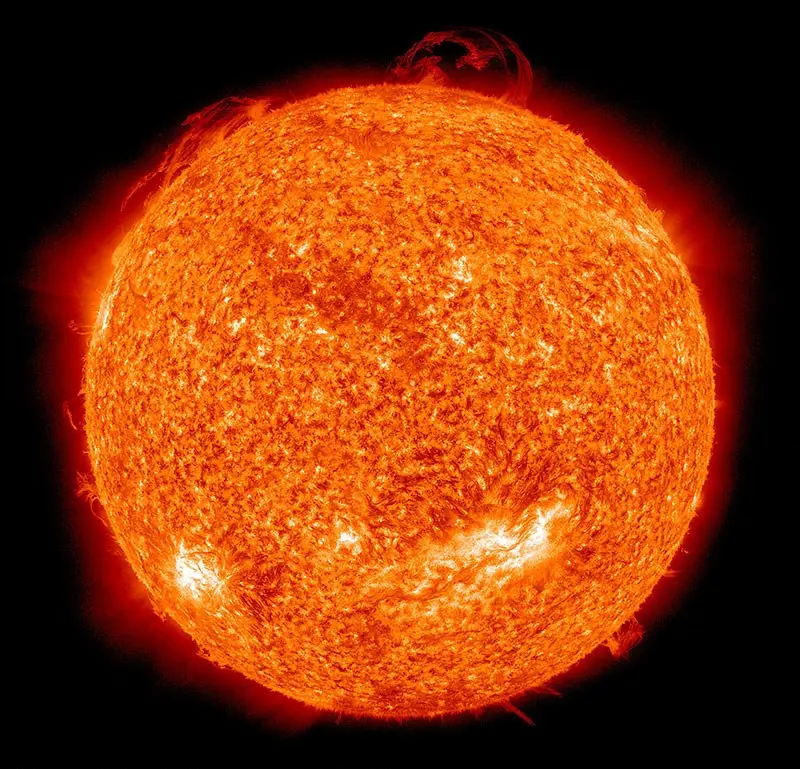

The award, to be spread out over five years, will support Lam’s work on developing reactor monitoring technology to help to achieve and sustain nuclear fusion reaction for generating power. Nuclear fusion is the same process that powers the sun and other stars, and it has the potential to provide an almost unlimited supply of clean energy.

“Currently, nuclear fusion technology is in the experimental phase, and achieving a stable fusion reaction remains a huge challenge,” Lam says. “While fusion reactions can be created, sustaining them for long periods for power generation is difficult due to the enormous amount of energy that must be managed to initiate and maintain the reaction.”

Image by NASA/SDO

Image by NASA/SDO

Lam is one of 91 early career scientists and engineers from 50 universities and 12 DOE national laboratories across the country who have been selected this year to receive a combined $138 million in funding for research covering a wide range of program areas, from high-energy physics to advanced scientific computing.

Lam’s funding will support his work on using machine learning to improve monitoring systems for “molten salt fusion blankets,” a critical component of nuclear fusion reactors that is used to produce additional nuclear fuel for the fusion reaction as well as to cool the reactor and transfer heat to steam turbines to generate power.

Harnessing the Energy Source of the Future

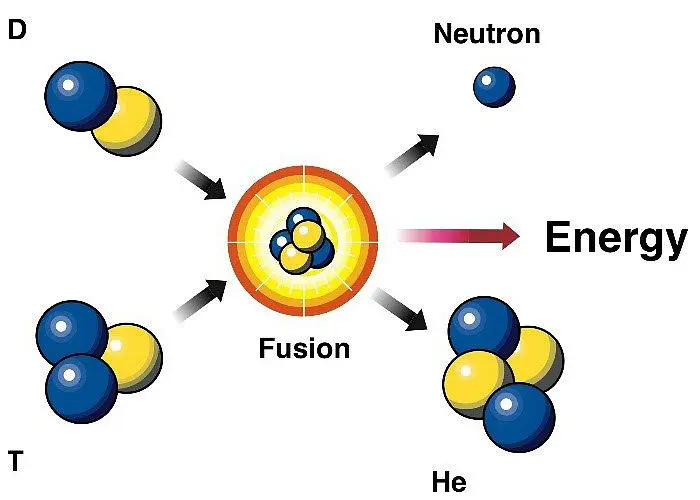

Unlike conventional nuclear reactors, which use fission reaction to split the nuclei of heavy atoms like uranium or plutonium into lighter nuclei to produce energy, in a fusion reaction, two light atomic nuclei – deuterium and tritium, which are isotopes (variants) of hydrogen – are combined, or fused, to form a single, heavier nucleus of helium while releasing energy and a neutron.

The molten salt fusion blanket system uses chloride-based or fluoride-based liquid salt mixtures that can operate at high temperatures. The molten salts are used not only for producing nuclear fuel and cooling the reactor, but also to serve as shielding to prevent high-energy neutrons produced by the reaction between deuterium and tritium from escaping outside the reactor and to protect reactor components from radiation damage.

Image by DOE

Image by DOE

In a fusion reaction, two light atomic nuclei – deuterium (D) and tritium (T), which are isotopes (variants) of hydrogen – are combined, or fused, to form a single, heavier nucleus of helium (He) while releasing energy and a neutron.

Lam says his technique will analyze and predict the behavior of molten salts with unprecedented accuracy and speed, allowing for the high-resolution tracking of oxidation states and structures of the salts’ metallic ions in real time, which are crucial for preventing corrosion and ensuring the safety of the fusion reactor.

“Traditional methods such as electrochemical and optical techniques struggle with the complexities of molten salt environments. They either degrade under the harsh conditions of molten salt fusion blankets or do not provide the necessary precision, especially under extreme temperatures and radiation,” he says.

By applying machine learning to experimental lab-based XAS data, Lam hopes to overcome these challenges, enabling better corrosion control and material stability in fusion reactors.

“This approach would benefit not only fusion, but it could also extend to other fields, such as catalysis, solvent processing, biochemistry, energy storage and many more that require monitoring of structurally complex materials,” he says.

A Great Technological Challenge

Lam points out that while producing energy from fusion on a commercial scale has not yet been realized, recent advancements in the field, including the development of high-temperature, superconducting magnets, could enable compact fusion reactor systems to be built and operated within the next decade. However, challenges like material stability and controlling extreme temperatures remain, he says.

“My research addresses one of these challenges – material corrosion in fusion blankets – and represents a key step toward making fusion a viable energy source,” Lam says.

He adds, “There have been breakthroughs in the ability to sustain fusion reactions for longer periods, but controlling the reactor’s internal environment, especially the molten salt, is crucial for rapidly scaling up fusion energy to a commercial level.”

The Early Career award is the second DOE grant Lam has received this year. In May, Lam and his collaborators from MIT and Stony Brook University won a three-year, $1 million grant for their work on understanding molten salt chemistry for safely and efficiently recycling fuels in molten salt fission reactors.