Image by Pexels

Image by Pexels

Take a walk through a forest, and you’re bound to come upon a spider web stretching from one tree branch to the next.

The intricacy of the web can leave a person in awe, but what is even more impressive is the individual silks that make up the web.

“Spider silks have desirable mechanical properties,” says Jessica Garb, an associate professor in the Department of Biological Sciences. “Some silks are tough, meaning they can absorb a lot of energy before breaking. Some have more tensile strength, while others are stretchier. Other silks have an impressive range of adhesion.”

For roughly two decades, Garb has studied the evolution and diversity of spider silks, whose properties prove attractive for bioengineered products, such as medical sutures, bulletproof clothing and seat belts. The National Science Foundation (NSF) recently awarded Garb a three-year, $344,000 Mid-Career Advancement grant to further her spider silk research through training at Tufts University under Biomedical Engineering Prof. David Kaplan.

“David Kaplan is well known for working with silk for biotechnology purposes,” says Garb, who continues to teach at UMass Lowell while undergoing training. “The training will give me new tools for my research.”

Understanding Silk Proteins

Spider silk is a natural fiber made of multiple proteins. When scientists determine the properties of silk, it’s usually at the fiber level; however, Garb says it’s beneficial to know which proteins contribute the most to each property.

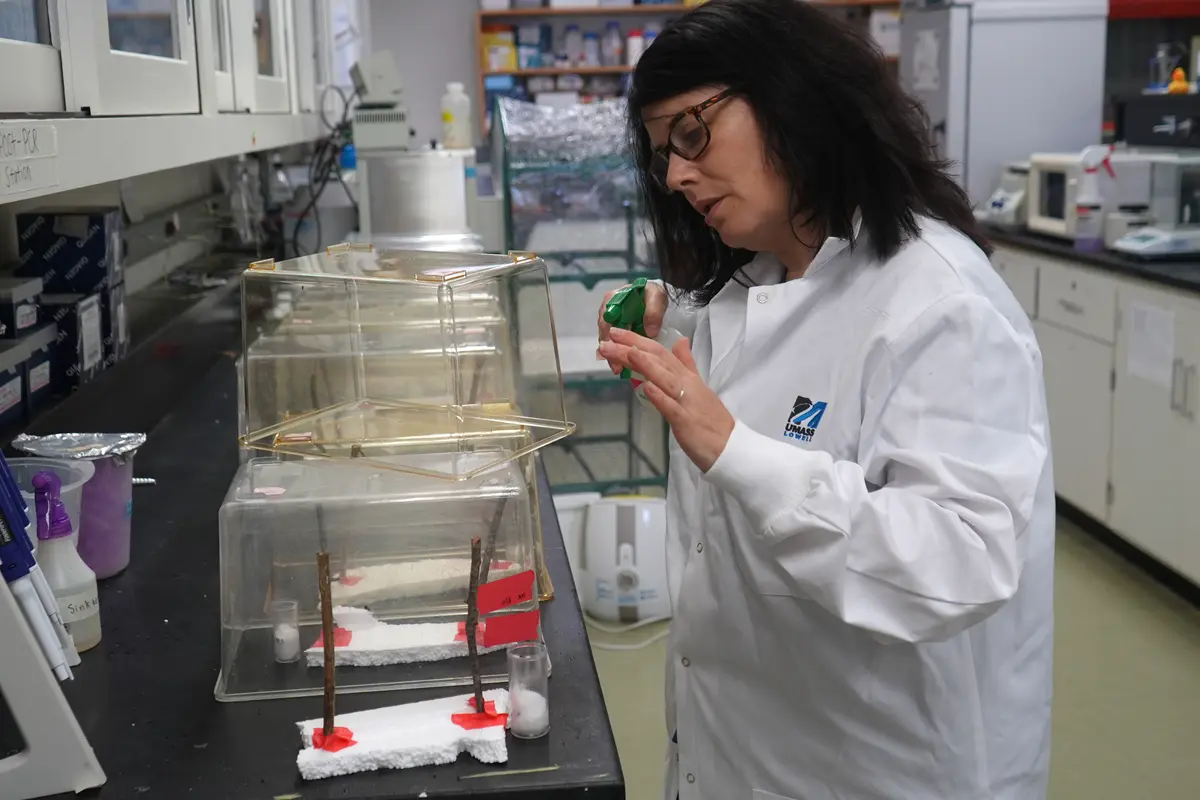

Image by Brooke Coupal

Image by Brooke Coupal

“You can test the properties of the fiber to say whether it’s very tough or very stretchy, but because the fiber is made up of different proteins, it’s hard to say which proteins are the most important,” she says. “If you can isolate and test a protein itself, then you can come up with commercial applications for the protein.”

Garb says extracting proteins from silk is a difficult task, but adds that the proteins can be artificially made through a technique known as protein expression. This is a technique Garb will learn in Kaplan’s lab.

“I am trying to make specific proteins that we have found in my lab that are very unique and interesting,” Garb says. “We think they may confer special properties like greater extensibility for certain kinds of silks, but we want to test the proteins because we don’t know for sure.”

“Being able to synthesize the protein and test it in isolation will be very helpful in pinpointing the properties of the protein,” she adds.

Garb sees her training as being useful in enriching student research opportunities at UMass Lowell. She is also looking to develop a new undergraduate course in silk biology after completing her training.

Database to Help Bioengineers

As scientists learn more about spider silk proteins, that information must be accessible to others looking to use the proteins to create better products. To make this happen, Garb plans to develop a spider silk protein database as part of her NSF project.

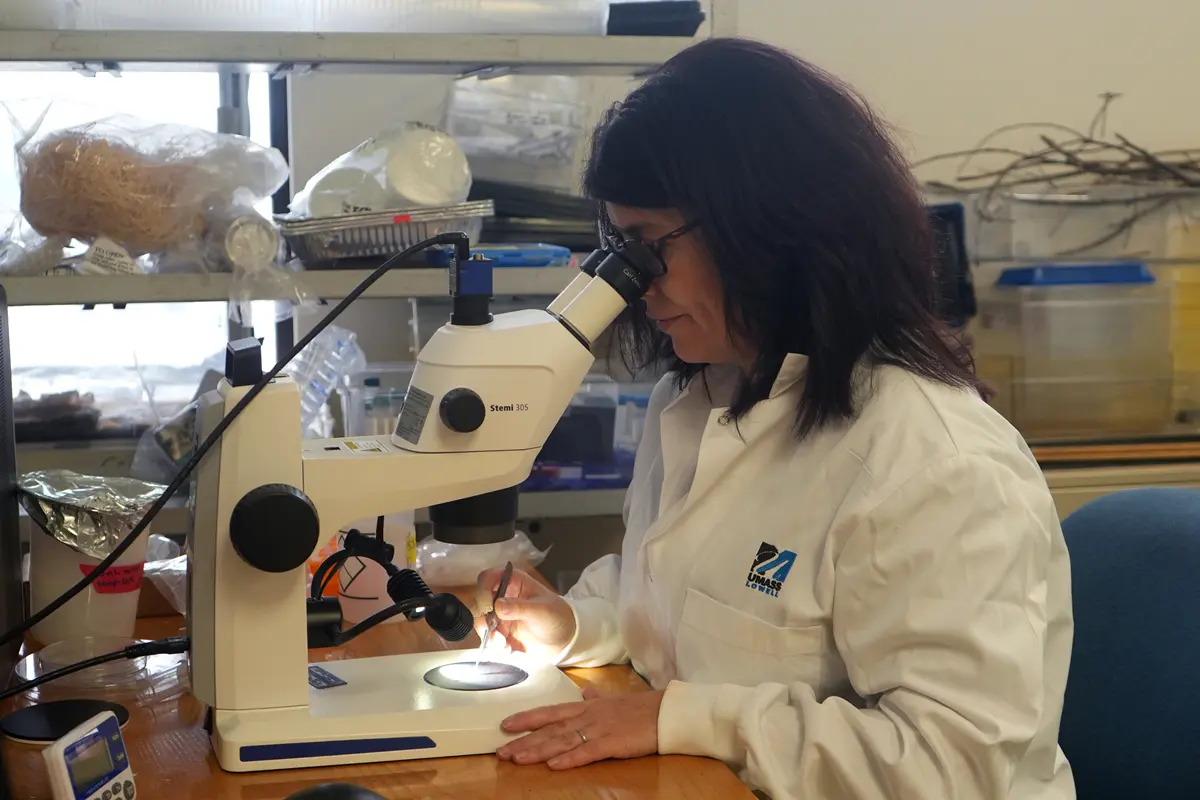

Image by Brooke Coupal

Image by Brooke Coupal

“Traditionally, people in the biological engineering world have drawn on a small number of silk proteins to make their materials,” Garb says. But with more than 50,000 spider species in the world, she adds that there is a “huge amount of untapped protein variations.”

The rise of genomics has made it easier to classify spiders and their silks, but unless a bioengineer is actively looking through the genomics literature, it can be hard to find information about spider silk proteins. Garb hopes the database solves the problem.

“The idea is to build more synthesis between evolutionary biologists and bioengineers,” says Garb, who plans on summarizing the current data on spider silk proteins for the database. “By incorporating certain silk proteins, bioengineers can make materials with better properties.”