Initiative Will Help Develop Supply of Trained Industry Professionals

07/29/2024

By Edwin L. Aguirre

Additive manufacturing, more popularly known as 3D printing, is one of the fastest-growing fields in the manufacturing industry. The technology is now being used to fabricate a wide range of complex, multi-material 3D structures and components, from microscopic parts used in medical devices to entire cars, houses, boats, aircraft and rocket engines.

According to Fortune Business Insights, the global 3D printing market size was valued at $22.39 billion in 2023 and is projected to grow to $150.2 billion by 2032.

Innovations in 3D printing and materials science such as liquid metal printing and nanoscale biomedical engineering, as well as the use of artificial intelligence in the printing process, mean that the technology will continue to expand and play an even bigger role in next-generation manufacturing, according to industry analysts.

To help meet the industry’s expected demand for highly skilled workers, the Science of Heterogeneous Additive Printing of 3D Materials (SHAP3D) Center at UMass Lowell has launched a workforce development program supported by the National Science Foundation (NSF).

Called START, which stands for Skills Training in Advanced Research & Technology, the program aims to train undergraduate students from community colleges and universities in fundamental research in additive manufacturing, based on areas identified by industry as top priorities.

Image by Edwin L. Aguirre

Image by Edwin L. Aguirre

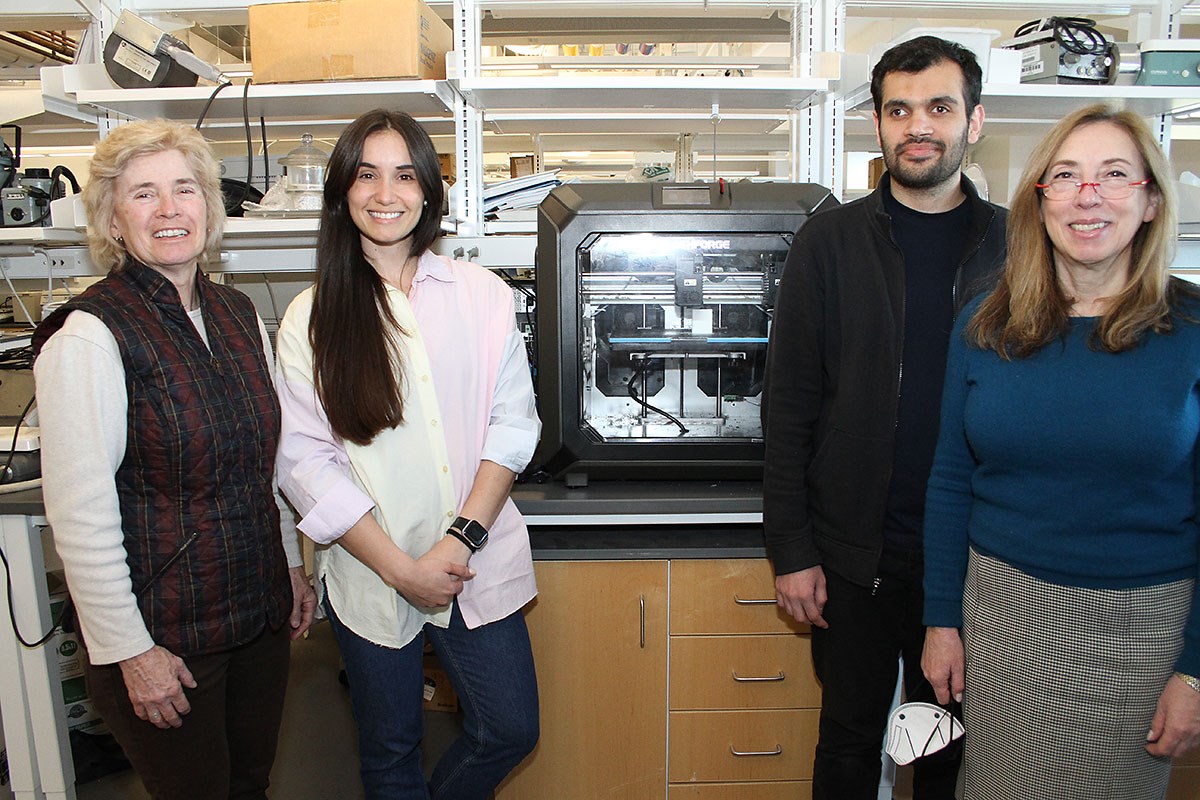

“START provides students with experiential learning opportunities on various projects at SHAP3D so they develop skills for careers in the additive manufacturing sector,” says UML Chemical Engineering Assoc. Prof. Nese Orbey, who co-directs START with Mead.

“The program also enables students to meet and network with members of the center’s Industrial Advisory Board,” Orbey says.

As an IUCRC, the SHAP3D Center received an initial round of NSF funding for 2018-2025 worth $1.44 million, which was combined with more than $1.76 million from industry. In May, the federal agency awarded the center a second round of funding for 2024-2029 worth $1.15 million. The goal is for university faculty and students from the SHAP3D consortium to work on industry-defined research projects and make the research accessible to industry members to help expedite the commercialization of new materials, printing methods and products.

Mead is the principal investigator for both NSF grants, with Orbey, Mechanical Engineering Prof. Christopher Hansen and Plastics Engineering Profs. David Kazmer, Carol Barry and Amy Peterson as co-PIs, and Patrick Drane as technical program manager.

START’s training program is supported by a $114,000 supplemental grant to the initial funding. The NSF hopes that the program helps in “fostering the growth of a globally competitive and diverse research workforce and advancing the scientific and innovation skills of the U.S.”

A Cutting-Edge Technology with Limitless Potential

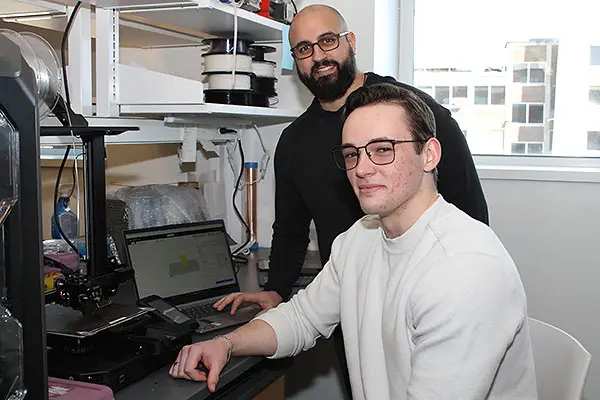

Four undergraduate students participated in the first cohort of the program as paid interns – UMass Lowell seniors Catherine Nkwantah and Justin Flynn and Middlesex Community College students Jodi Zangari and Hussein Awada.

Image by Edwin L. Aguirre

Image by Edwin L. Aguirre

Two UML graduate students, Nathalia Diaz Armas and Daniyal Shoukat, who are working toward their doctorate on projects funded by SHAP3D, helped to train the students.

“3D printing is important because it enables customized and personalized products,” says Nkwantah, who graduated in May and is now pursuing a master’s degree in chemical engineering. “It efficiently uses materials, reducing waste and contributing to sustainability. It is a cutting-edge technology with limitless potential.”

Flynn agrees. “3D printing is incredibly important as it is the future of manufacturing and prototyping,” he says. “It is capable of creating seamless and continuous shapes that no other type of manufacturing can. Additionally, it is capable of using a wide variety of materials to print, ranging from flexible rubber to organic tissues to various metals.”

Some of the projects on which the student researchers focused included designing and printing a circuit board enclosure for a microwave curing system, studying how differing orientation of two filament materials affects the bonding strength between the filament layers, and trying to improve the print quality of multi-material lattice structures such as honeycombs.

“Having the opportunity to work on real, funded research projects has been eye-opening for me,” Nkwantah says. “The possibility of being published and doing work that has a significant impact on the additive manufacturing industry is not only exciting, but also extremely rewarding. Our projects are a collaborative effort, and the ability to work well with others is a valuable skill.”

Image by Edwin L. Aguirre

Image by Edwin L. Aguirre

“I really enjoyed getting to work on these projects,” says Zangari. “The program enhanced my understanding of various 3D printing and design techniques as well as hardware and software, which broadened my knowledge and experience overall.”

The students also attended the Industrial Advisory Board meetings last fall at the University of Connecticut and in spring at UMass Lowell.

“The meetings were great learning experiences and helped us to better understand the funding process in research and learn cutting-edge technologies happening in 3D printing right now,” Zangari notes.

Diaz Armas, who is in her second year working at SHAP3D as a plastics engineering Ph.D. student, found the program to be an enriching experience.

“I have been involved not only in fascinating research, but also gained significant networking opportunities and valuable skills,” she says. “This project has provided a great opportunity for growth, both academically and professionally, and I believe it will greatly benefit my future career.”