Lowell Makes 3D printing N95 alternative masks as shortage looms

Image by Lowell Sun/Robert Mills

Image by Lowell Sun/Robert Mills

03/25/2020

Lowell Sun

By Robert Mills

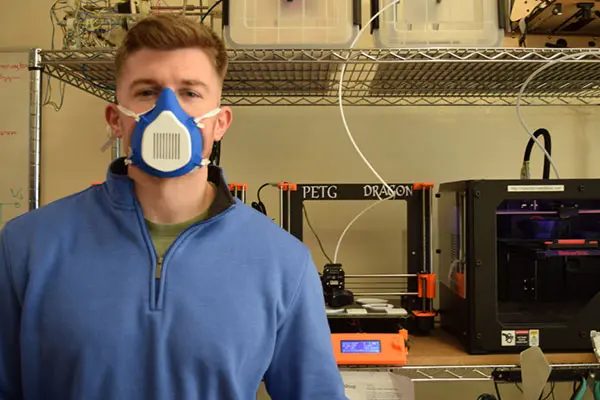

A dozen 3D printers hum in the background at Lowell Makes on Merrimack Street, each meticulously creating a new N95 alternative mask to help local health care workers, when an alarm sounds on Mike Rushton’s cellphone.

“That means my printer at home should be done too,” he says, as he begins writing a text message to his wife to ask her to start a new print job on the printer in his home.

The seriousness with which the local makers are taking a new initiative to create the masks, along with help from dozens of others around the region, is immediately obvious.

Rushton and over a half-dozen helpers in the Merrimack Street building have been working since last week to create hundreds of N95 alternative masks for local hospitals and others who need them.

As the 3D printers hum out front, taking hours to print a frame and parts for each mask, Lowell Makes members work in a back room adding filters, straps and other parts to each mask. None of it is close-quarters work. It’s the age of social distancing. There’s a plan to sanitize everything once it’s assembled.

A shortage of industrially manufactured and government tested N95 masks and other personal protective equipment has alarmed doctors like Dr. Ashish Jha, professor of global health at Harvard University.

On Friday, Jha told a telephone town hall hosted by U.S. Rep. Lori Trahan that shortages of protective equipment and ventilators was concerning in light of how hard COVID-19 hit health care workers in China and Italy, where it killed and sickened thousands.

“Here I’m actually worried about where we are as a country,” Jha told the town hall. “I can’t speak about individual hospitals, but we are, as a country, in short supply of PPE.”

While efforts to create “open source PPE” are springing up all over the country, the effort to create it in Lowell began with just an idea and a simple Facebook post.

Meredith Ritze, a registered nurse who works in the emergency department at Lowell General Hospital, said she originally went online looking to see if anyone could donate N95 masks, and made a post offering to get the masks to the hospital if anyone had donations.

Instead, she was contacted by Rushton, who had already begun working at home with what he believed was the best of several N95 alternative mask designs available from an online community of other makers.

Rushton didn’t want to donate masks he already had. He wanted to produce them, and asked how many Ritze thought the hospital might be able to use, and whether she might have advice on just what was needed.

Her answer was 100 or more.

“I’m like well I’m not going to do that just at my house. It would take six hours just to print a couple of them,” Rushton said. “So I came down here and started getting printers going and I put a call out to our group here and said hey guys we need to get moving on this and start helping out. It’s kinda grown from there.”

At about the same time, Rushton also heard from a friend who is a respiratory therapist at a local hospital, and that friend too needed over 100 masks.

“They wanted to pay for them but we’re not going to charge them,” Rushton said.

In addition to being joined by about 20 Lowell Makes members, Rushton said about 100 people have sent the group messages offering to help from their homes. Some of those messages were from so far away the group suggested the senders check with hospitals and makers groups closer to their own homes, said Lowell Makes President Sam Burdett.

“I think we can turn out 50 or more a day at this point,” Rushton said.

The group is working with Lowell General Hospital to have the masks tested before they’re accepted and deployed there, but several other hospitals and organizations in the region have already fit tested and taken delivery or requested delivery.

The group is nevertheless playing it safe and including a disclaimer with the open source masks.

“We are collaborating with healthcare professionals and other makers to develop open-source personal protective equipment; however, we caution that these items have not been tested or approved for medical use by any relevant authorities. Lowell Makes makes no guarantees that these masks will prevent transmission of COVID-19. Please continue to adhere to current CDC guidelines regarding COVID-19 and use open source PPE at your own risk.”

With demand for N95 masks so high both locally and worldwide, Rushton said there is no end in sight for the effort to produce the open source masks, and that the group could still use more help from anyone with a 3D printer at home.

Rushton said the computer file and other instructions needed for a 3D printer to make a mask is available on the Lowell Makes website.

“We’re asking them to just print those and give them to us as you finish, and then we’ll take care of the rest,” Rushton said.

Burdett said there is also a link on the group’s Covid-19 response page for anyone who wants to make a donation to help pay for supplies like elastic bands for the masks, raw materials, or the rather expensive air filters that are required.

Ritze, who emphasized that she was speaking and helping out as a volunteer and not on behalf of the hospital, said she was “blown away” by the offer to help.

“I had no idea that they could even do this, never mind that they would want to help,” she said. “The community has been so supportive and I’m very thankful. I’ve grown up in this community and I’m due to graduate as a nurse practitioner from UMass Lowell. This is my community, and everyone has been so supportive.”

For more information on the effort, or to contribute to it, visit: https://lowellmakes.com/covid-19-response/.